Desoutter ชุดเครื่องมือสำหรับวัดค่าแรงบิดและการ Calibrate สำหรับ Electric Nutrunner

Data Analyzer

This generation of Delta analyzer is the compact portable solution to monitor all types of production tools at just 500g. Combined with standard Desoutter DRT or DST transducers it’s capable of calibrating pulse tools, electric nutrunners or torque wrenches. Divided into three models for Torque measurement only (DELTA 1D), Torque & Angle (Delta 6D) and capable of residual torque check and production strategy with DWTA wrench (Delta 7D).

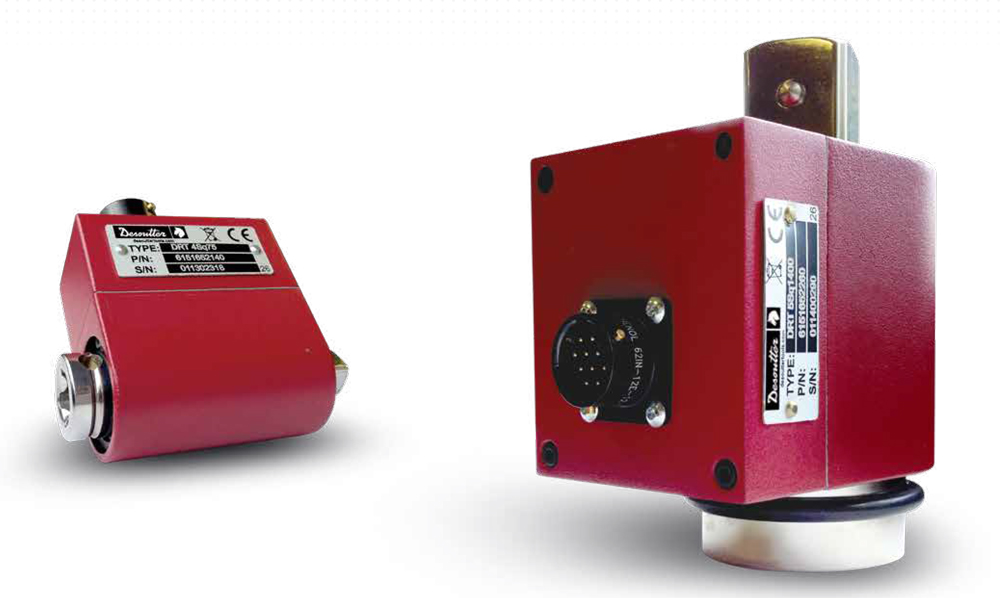

Digital Rotary Transducer (DRT) for Torque & Angle

DRT-4

The DRT-4 rotary transducer series are designed to measure torque output (Only) of any non-impact assembly tool, directly on your application in dynamic mode.

Features :

- Torque range from 0,2 to 10000 Nm (0.15 to 7375 ft.lb).

- Strain gauges transducer: - sensitivity 2mV/V - accuracy +/-0.35% of torque reading.

- Built-in smart chip memory with calibration features: - type of transducer - sensitivity nominal load - serial number.

Benefits :

- Automatic recognition thanks to internal me-mory chip storing main data values elimina-ting any setting mistakes and time losses.

- High reliability due to immunity from external noise thanks to digital communication.

- Communication to data analyzer not sensiti-ve to the cable length.

- Long life durability thanks to industrial design from transducer to housing.

DRT-5

The DRT-5 series associated with a Delta 6D or Delta 7D are including an Angle measurement encoder to allow both Torque AND Angle quality controls (preferred series in case you are using Angle strategies and/or monitoring).

Features :

- Torque range from 0.2 to 5000 Nm (0.15 to 3685 ft.lb).

- Angle counting system 0.5° resolution.

- Strain gauges transducer: - sensitivity 2mV/V - accuracy +/-0.35% of torque reading.

- Built-in smart chip memory with calibration features: - type of transducer - sensitivity nominal load - serial number.

Pulse Static Transducer (PST)

Designed for testing hand wrenches, click wrenches, Pneumatic Pulse tools and electric nutrunners, the Pulse Static Transducer is the ideal solution to provide a periodic and static mean of control for audit at the station and will cover all your assembly tools in the production area.

Features :

- Torque accuracy +/-0.35% of torque reading. Built-in smart chip memory with calibration features:

- type of transducer

- sensitivity nominal load - serial number.

- Lever to clamp the Joint simulator firmly for impulse tools

- Recommended for Pulse tools

Digital Static Transducer (DST)

DST Static Transducer series fit all assembly tools except impact and impulse tools. These are mainly recommended for continuous drive electric tools and hand wrenches.

Features :

- Torque accuracy +/-0.35% of torque reading.

- Built-in smart chip memory with calibration features:

- type of transducer

- sensitivity nominal load

- serial number.

Calibration Bench

Embedded Transducers :

Assembly tools calibration process requires a flexible and versatile solution, high quality performance even in production lines. Desout-ter Tools is proud to present the Delta Cart, an ergonomic and attractive solution to improve quality in assembly processes.

- Delta Cart offers a wide torque range since it can be configured up to 4 static transducers to cover from 0.2 Nm to 1 000 Nm (0.15 to 738 ft.lb) in a very compact dimensions (510mm width), making the Delta Cart the ideal solution for tool testing in assembly production lines.

- Embedded PC equipped with wide 12” color touch screen lets operators to start tool testing in a few seconds and few steps.

- Delta Cart includes all adapters, reaction bars and suitable joint similators. Optional ISO RIG for torque wrench to eliminate operator influence during calibration, reducing efforts for high torque range.

Delta Cart Tool Calibration

The Delta Cart is able to follow your tools during the complete life span: by performing capa-city test (Cm/Cmk) before tool is introduced into production, or monitoring tool performance during production assembly process by performing Statistic Process Control (SPC) test.

Technical Features :

- Configurable torque range from 1 Nm to 1000Nm

- Torque reaction bar and joint simulator included

- External DRT communication for in-line calibration

- Angle Strategy with external DRT5

รายละเอียดเพิ่มเติม >>> คลิก!

(+66) 2712 0898

(+66) 2712 0898